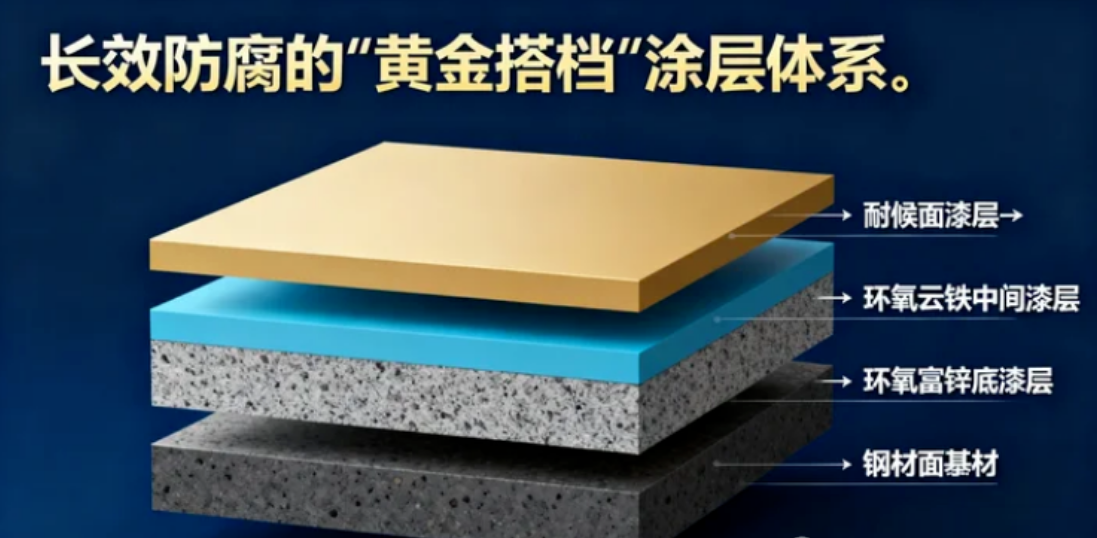

Hello everyone, bosses, engineers, and masters of the construction team!Those of us in the dry coating and anti-corrosion industry are certainly no strangers to epoxy zinc-rich primers.It is like a "personal armor" for anti-corrosion of steel structures. Its anti-rust ability is excellent, especially relying on the "sacrificial anode" function of zinc powder to electrochemically protect steel, and its reputation has always been online.

However, we have received a lot of inquiries recently and found a very common and worrying phenomenon: In order to "save trouble" or "money money", some friends directly use the epoxy zinc-rich primer alone without any topcoat!Today, let’s break it up and talk about it: Can epoxy zinc-rich primer be used alone?Why do we strongly discourage this?

1. Let me start with the conclusion: Strictly speaking, it can, but the conditions are extremely harsh!

Referring to some technical information and our many years of field experience, under the following extremely ideal circumstances, it is barely feasible to use it alone:

Ultra-short-term temporary protection: For example, at a construction site, the steel structure is temporarily left for a while (usually no more than 1 year), and it needs to be completely repainted later.

The equipment in the "greenhouse" is placed in a completely indoor warehouse without sunlight, moisture, or chemical fumes.

Extremely dry "retirement places": In some particularly arid outdoor areas, the structure is not very stressed and frictional.

Do you think these conditions are quite "hypocritical"?There are so many "utopias" in the real industrial environment, seaside, factories, bridges...?Therefore, in 99% of application scenarios, letting the epoxy zinc-rich primer "streak" is tantamount to burying hidden dangers.

2. Why not let it fly solo?Four major flaws, all of which hurt my heart!Flaw 1: It is naturally "afraid of the sun" (poor weather resistance)The core adhesive of epoxy zinc-rich primer is epoxy resin.Everything about this thing is good, but it has a fatal weakness - it is not resistant to UV rays.After being exposed to the sun for a long time, the coating will slowly "age", manifesting as chalking, loss of gloss, and the surface turning into a layer of loose powder.This is not only ugly, but more importantly, once this layer of powder falls off, the zinc powder and steel inside are gradually exposed, and the anti-corrosion ability plummets.

Flaw 2: Zinc powder “consumption is accelerated” and its lifespan is discountedIts rust prevention relies on zinc powder to actively "sacrifice" itself.If a topcoat is used to seal it like a "protective shield", zinc powder consumption is slow and controllable.Once there is no topcoat, zinc powder will directly face wind, rain and atmospheric pollutants, and the consumption rate will be greatly accelerated.Equivalent to the "blood volume" that could last for 10 years, it may be exhausted in three to five years, and the life span of the entire anti-corrosion system has been seriously reduced.

Fault 3: The appearance is "offline" and really doesn't look good.The dry film of epoxy zinc-rich primer is usually dusty or silvery gray, with a rough surface.For many buildings, factories, and equipment that pay attention to appearance, this decorative effect is basically zero.Nowadays, many projects require not only anti-corrosion, but also beautiful appearance and color marking. It cannot meet the needs alone.

Fault 4: Calculate small accounts and suffer big losses (higher overall cost)At first glance, applying one or two less coats of topcoat may seem like a saving in material costs and labor.But think about it: because there is no topcoat protection, the primer ages quickly and the zinc powder is consumed quickly, resulting in a greatly shortened maintenance cycle.Maybe someone else painted it in matching colors

Copyright © 2025 Weifang Xingyuan Paint Industry Co., Ltd

SitemapThis website uses cookies to ensure you get the best experience on our website.

Comment

(0)