Hello everyone! We are a professional manufacturer with many years of experience in coating production and construction.

Today, I want to talk to you about a problem that many users have encountered: Why does high-performance Fluorocarbon Paint sometimes crack? Fluorocarbon paint is known for its durability and beauty, but if cracks appear soon after construction, it will not only affect the appearance, but may also shorten the service life. Don't worry, today we will use vernacular to reveal the "crack crisis" behind it step by step from four aspects: substrate, putty layer, construction and environment! I hope I can help you avoid pitfalls. If you have technical questions or purchasing needs, please feel free to contact us~

1. Reasons for the substrate: The foundation is not strong and the earth shakes.The substrate is like the foundation of a house. If it is not treated properly, no matter how good the fluorocarbon paint is, it will be in vain. Imagine that if there is dust, oil or rust on the surface of the substrate, the paint film will not stick firmly and will easily peel off and crack like a sticker on a dirty wall. What's more troublesome is that if the substrate itself has cracks or holes, when the temperature changes, the substrate expands and contracts, which will transmit pressure to the paint film. Over time, the paint film cannot withstand this force and will naturally crack。

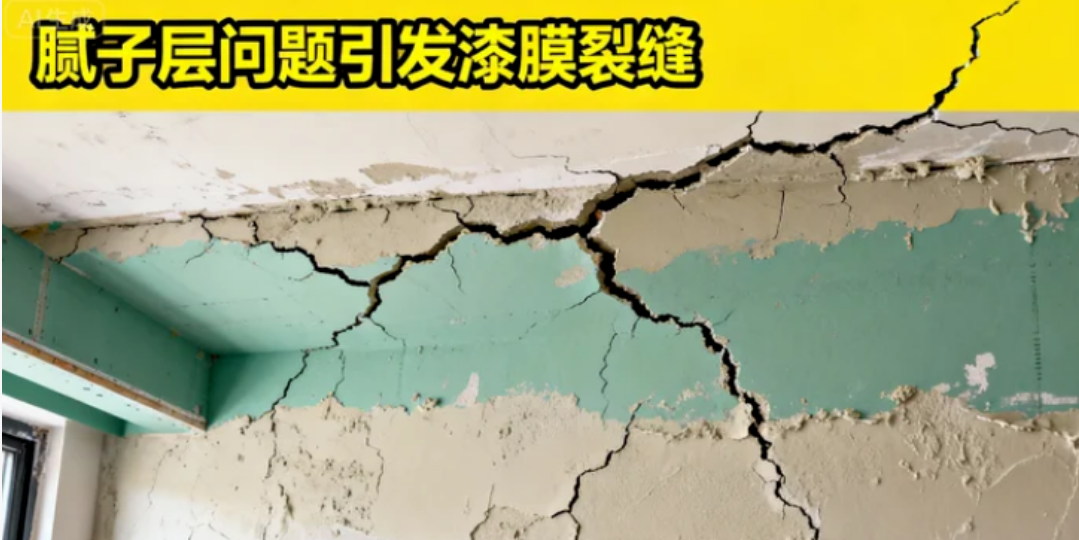

Reasons for the putty layer: If there is a problem with the middle layer, the paint film will suffer accordingly.

The putty layer is responsible for leveling during fluorocarbon paint construction, but if it is "disobedient", it will also become a "fuse" for cracks. For example, if the putty layer is too hard and has poor flexibility, it will not be able to expand and contract when the substrate is slightly deformed. It will crack itself first, and the paint film will suffer. In addition, if the putty dries too quickly, the internal moisture will disappear all at once, which will lead to uneven shrinkage and internal stress, and the paint film will easily "unbear" and crack.

Reasons for construction: details determine success or failure, one step is wrong and the other is wrong

The construction process is the hardest hit area for cracking of fluorocarbon paint. If many small details are not paid attention to, big problems may occur. Let’s elaborate on a few points:

The coating interval is too short: If you rush to apply the next layer before the inner layer of paint is dry, the inner layer will shrink when it dries, pulling and damaging the outer paint film, causing wrinkles or cracks. It's like putting on wet clothes and then putting on dry clothes, which get wrinkled when you move them.

Improper addition of curing agent: If too much curing agent is added, the paint film will harden quickly, but it will become brittle and easy to crack; if the wrong curing agent is used, it will not match the fluorocarbon paint, just like a key that is not in the lock, and will not form a strong structure at all.

Unmatched or excessive thinner: Adding unmatched thinner or adding too much will destroy the molecular structure of the paint, reduce flexibility and adhesion, and the paint film will "unbearable" when the environment changes.

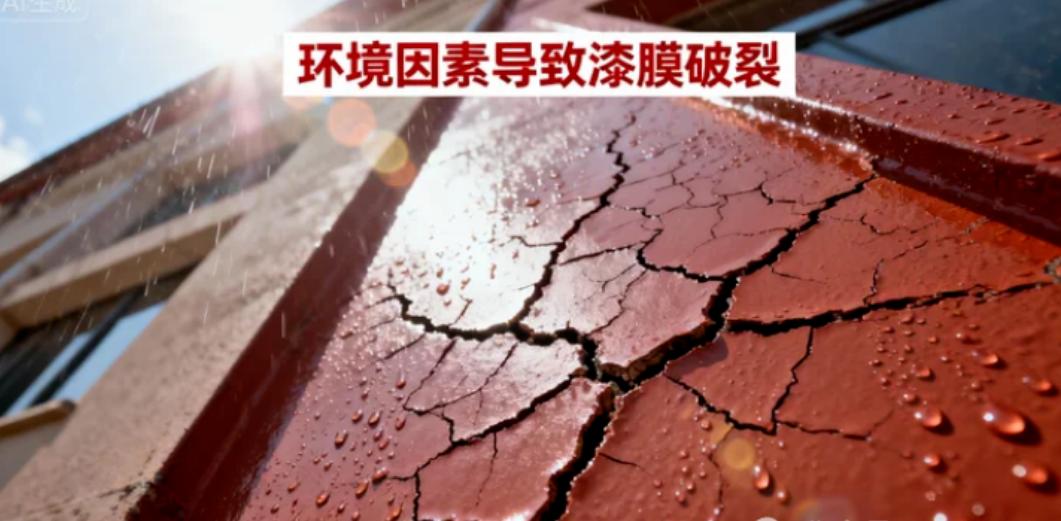

The coating is too thin: The paint film is too thin, like a layer of paper, which cannot withstand external forces and is prone to cracking. It is recommended to construct according to standard thickness to form a solid protective layer.Environmental reasons: The weather and location are not conducive, and the paint film is also "temperuous"

Environmental factors are often ignored, but high temperature and humidity are the "invisible killers" of cracking. At high temperatures, the paint film dries too quickly, resulting in high internal stress and easy cracking; at high humidity, the primer cannot dry thoroughly, and the primer is still "moving" after the topcoat dries, which will break the topcoat. Therefore, be sure to check the weather forecast before construction and choose a mild and dry day so that the paint film can cure "comfortably".

Copyright © 2025 Weifang Xingyuan Paint Industry Co., Ltd

SitemapThis website uses cookies to ensure you get the best experience on our website.

Comment

(0)